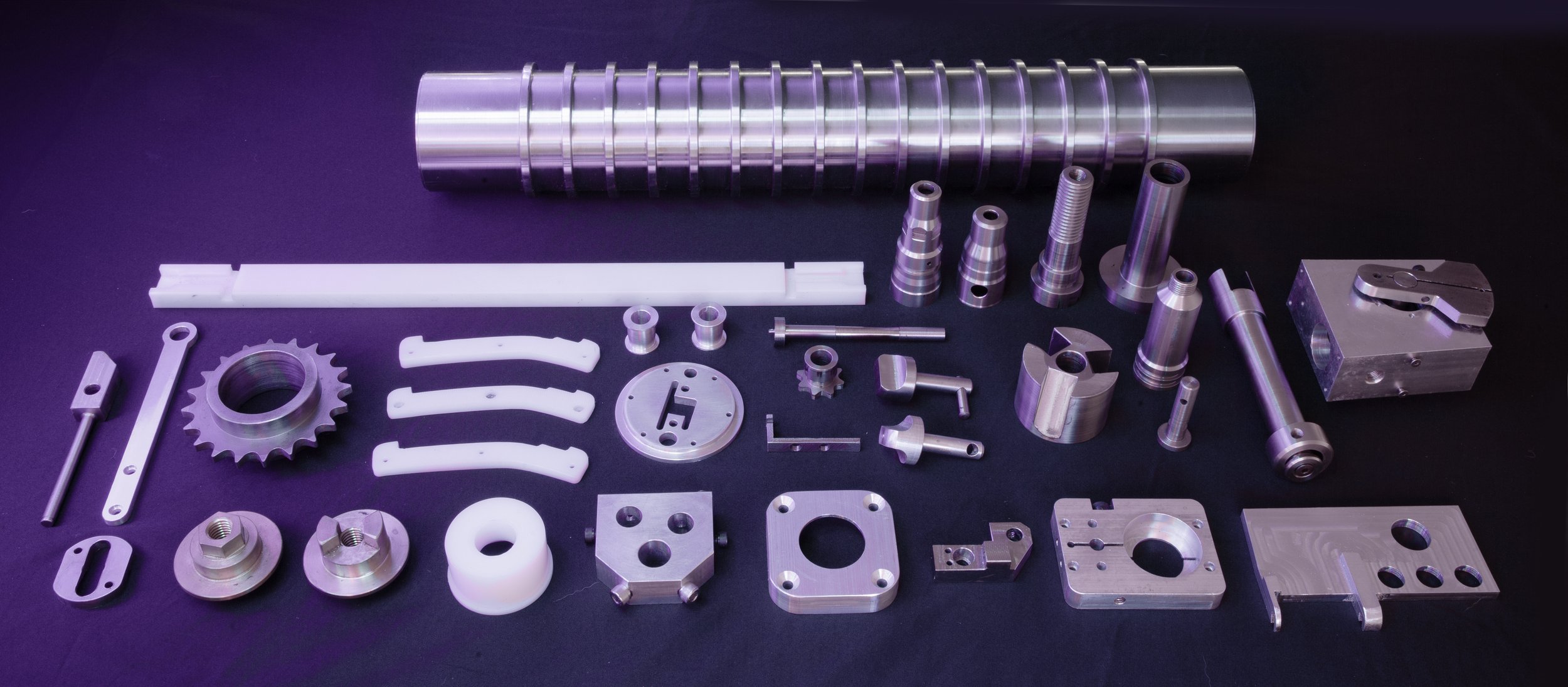

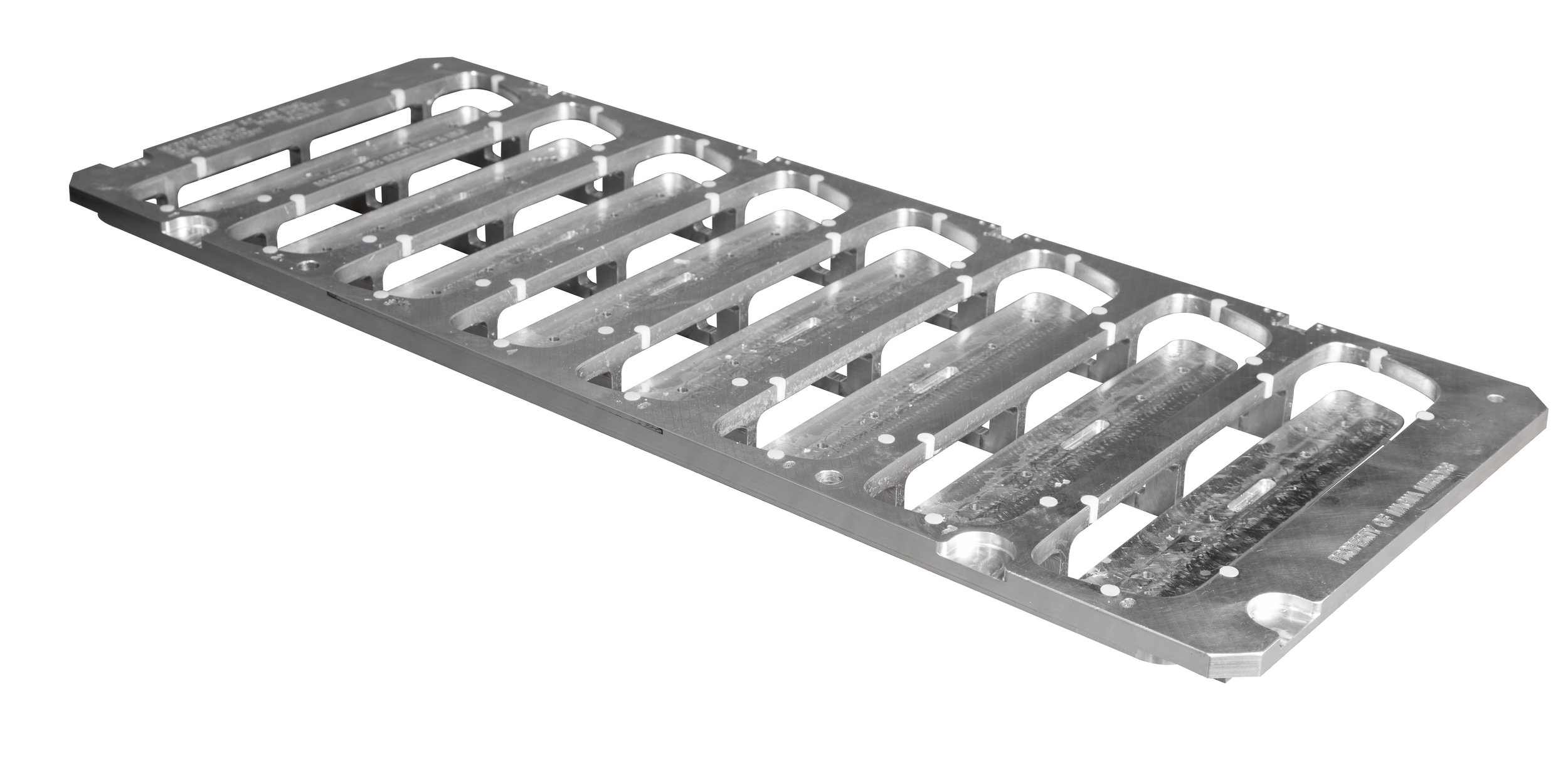

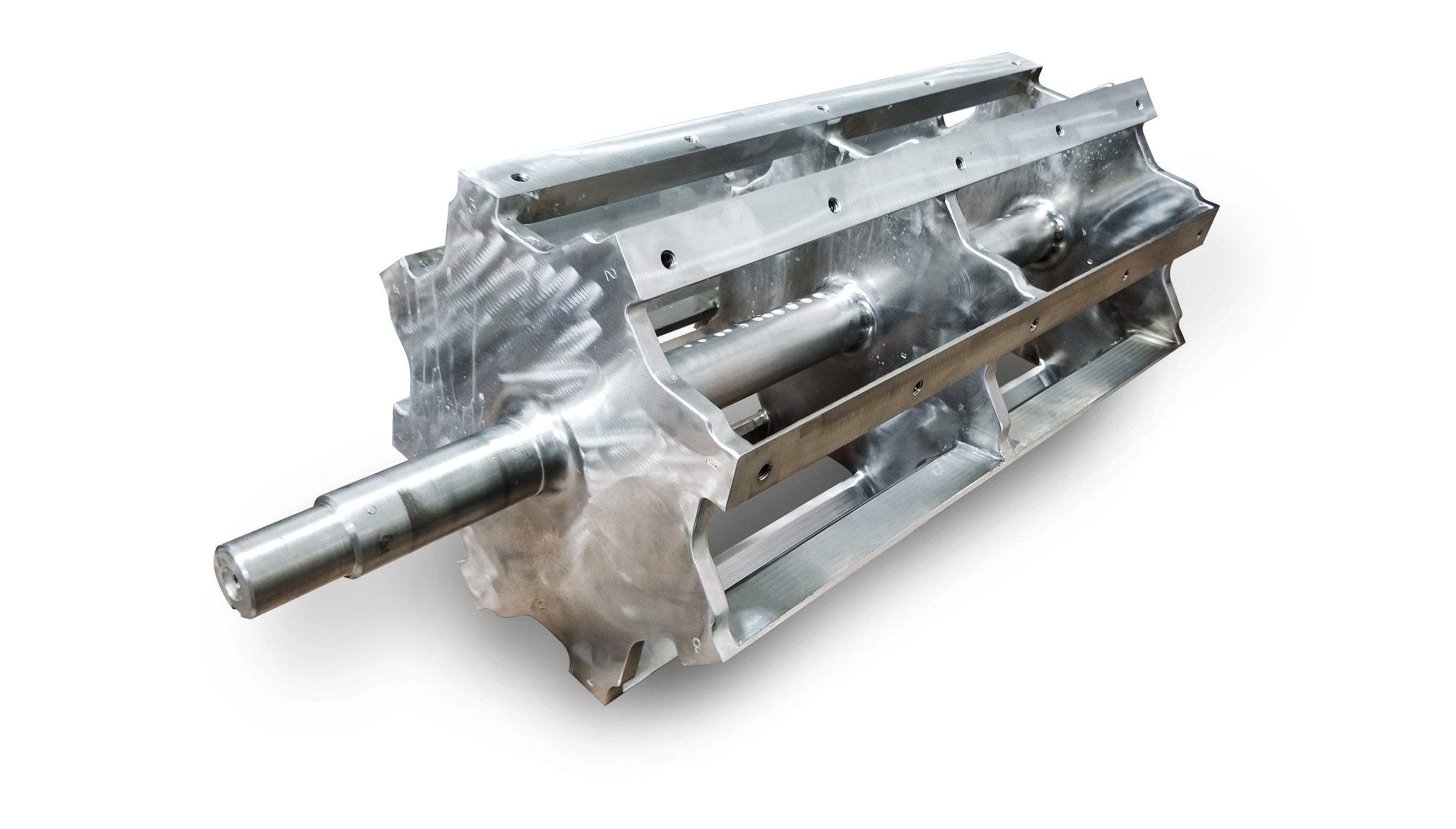

CNC Machining & Turning • Fixtures • Prototypes • Production Runs

We CNC things differently.

In our early days, we did things the old fashioned way, old school lathes, milling, grinding, cutting, drilling and stamping. Big and small machines with cranks, dialed in with calipers, raw skill and a good eye. We were educated in the die making heydays and we're proud of what we've learned along the way.

It's what's laid the foundation of knowledge, craftsmanship, and passion for precision that we put into everything we CNC today. This kind of expertise not only gives us a critical edge in CNC machining, but valuable capabilities where traditional machining is needed.

Innovative, flexible, streamlined.

Yep. We think small is better.

Being small can have huge benefits for our customers:

We're really good at producing just one part, reverse engineering difficult parts, and machining small production runs that others won't touch.

We operate very efficiently to keep our overhead down so we can offer a better value.

Your customer service guy is also the senior engineer and project supervisor in charge of quality control (and just happens to own the company).

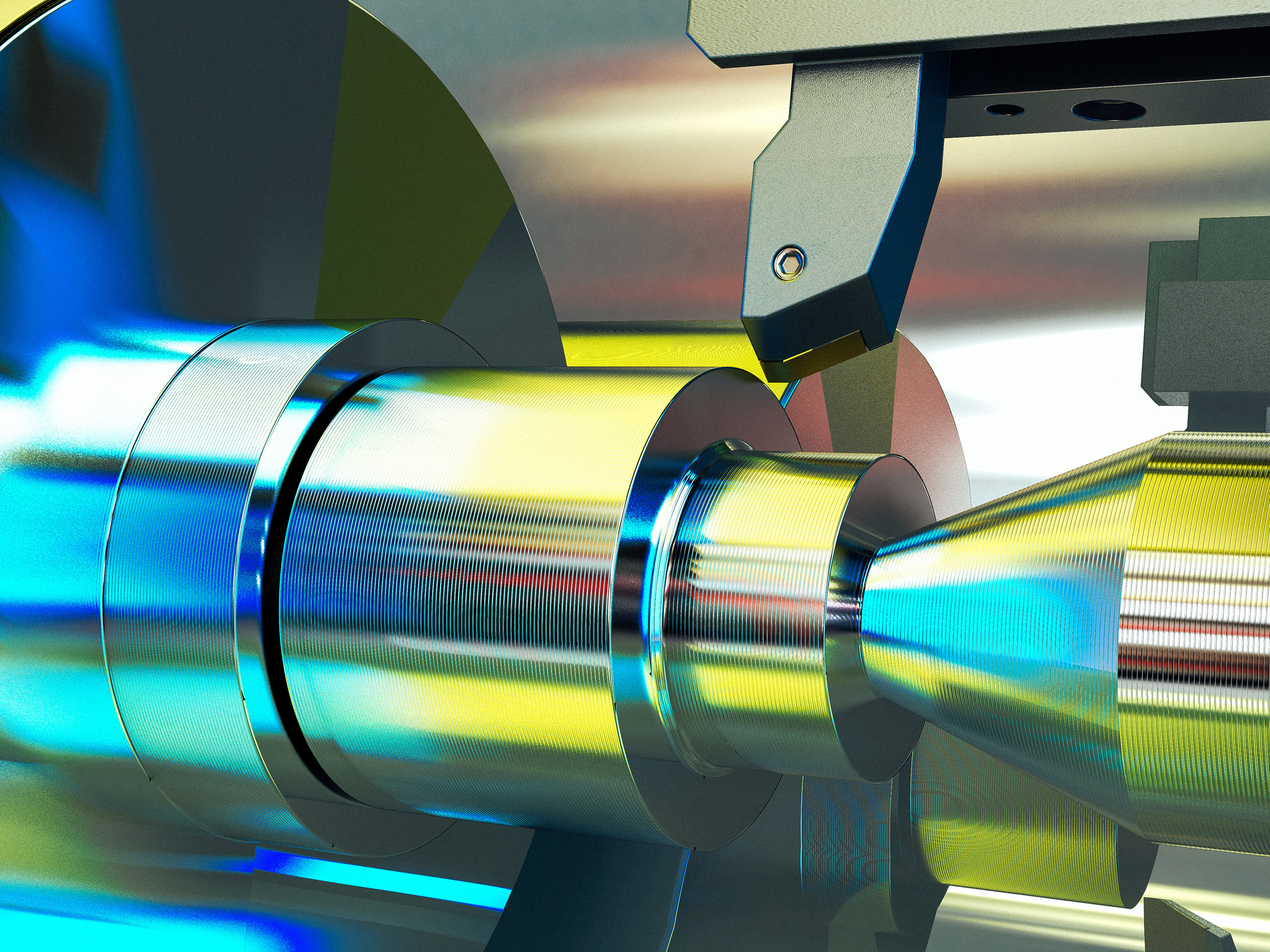

We've recently made some bold equipment upgrades

We're excited to show off our most recent updates in 4 Axis CNC Milling and Turning. These investments expand our ability to machine even more complex geometry with tighter tolerances and quicker turnaround.

See our latest upgrades along with a full list of capabilities Here.

A few customers we've served

GR Spring and Steel

Tesla

General Motors

Auto Die

Ford

Chrysler

BMW

Fiat

Volkswagen

Range Rover

Our Capabilities

Follow the link below for a list of everything in our wheelhouse.

Who is Borgia CNC?

Want to know who you'll be working with? Follow the link below to learn more about who we are.

Have a Question?

If you have a question about us, our capabilities, or anything else, follow the link below to drop us a line.